Re-routing CX Brake Wear Warning Wires

CX brake wear warning light wires break.

Close-up of broken wire AND sheathing

On all the CXs I've ever purchased these wires were broken, or removed because they broke. With broken wires there is no warning of pad wear, or false warnings of worn brake pads.

Routing caution: Clearance between the brake calipers and wheels is quite tight, so how you route the wires from the brake pads at the caliper is important to avoid failure at that point.

Solution

The factory route, once clear of the caliper, nearly always

results in broken wires. Only in cars not driven often have I seen unbroken wires.

Here you will learn how to route the wires to prevent them from ever breaking.

Two alternate routes were tested over a period of years. One route, a simple drape of the wires

slightly behind the brake hose, has proven unbreakable. The second route attached the wires to the brake line

with the thinking that this would help protect the wires. However, the wire broke near where it was clamped at

the sub-frame.

Original Route

The original routing is shown in the photos below.

Overview of the original brake wire route.

The wire is routed (inside a rubber sheath)

- From the caliper forward, behind the upper pivot

- Downward behind the brake vent mount to the bottom of the steering knuckle

- Around the pivot of the lower arm

- Strapped to the lower suspension arm

- Folded in a U shape horizontally along the lower arm (where it pivots) and clipped to the frame

- Up the side of the 'tower' on the front sub-frame

- Connected to the harness inside the engine bay.

Overall photo showing how the wires leave the brake pad area. Note the wires are secured under the spring, against the retaining rod.

Because clearance between the caliper and the inside of the wheel is very tight the wires are secured under the anti-squeal spring (here a slight modification is made, a sheath keeps both wires together) to ensure they do not become abraded and cause a false indication, and eventually fail.

This part of the path is exactly as the factory designed and must be retained.

Close-up of broken wire AND sheathing

The main problem lies in the bend at the lower ball joint. This photo shows a common break. You can see that this break is complete. We could fix it, but that really means running new wires since a fix in this stressed area will quickly break again. We could put a splice in the vertical section behind the brake duct (not shown) but again, we'll get the break again in a few years, or less at this very spot!

A alternate to the route shown below may be to run directly from the caliper over to the upper arm, across the upper arm then up the frame, leaving slack as needed. I've not tried this, but notice newer vehicles use a similar route. Additionally it may pay to use a different style of wire where the entire wire is smaller and fully sealed, IOW molded into a cable. This could prove to last longer and have a better appearance. I will be doing this on the next CX I repair and will report on it's success.

The New Route

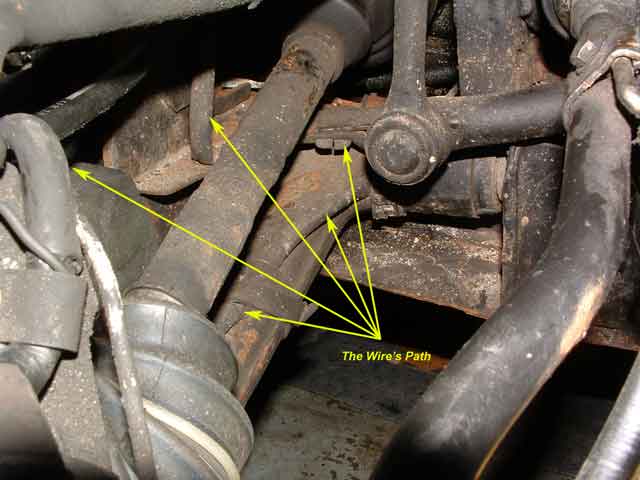

Below is the new route from the caliper. The wires pass between the rotor and ball joint, just keep it tight and use the sheath. Notice the wires exit the caliper by passing under the spring.

New wire route at caliper

In this route we've chosen to run the wire in front of the upper ball joint. This puts it perilously close to the rotor, so clamp it well to prevent movement. Since the wire and steering knuckle move together this does not pose too much of a problem.

Finally, the wire is allowed to hang from caliper to subframe. Do not be tempted to secure it, that only ends in failure.

Wires exit the brake caliper without being secured.

Wires at the sub-frame, again not secured until inside the sub-frame.

THIS PATH FAILS. Attempted to secure the wire to the brake line, but it failed so we no longer secure the wires as shown here.

Wiring Notes

If you don't have the original wires you may be a bit confused about how to wire them. Inside the engine bay are two wires, near the sub-frame, one green and one brown, twisted together. The brown wire runs ground to the steering knuckle and is bolted to the steering knuckle with the bolt holding the wire clamp (you can see the ring connector in this photo). The green wire runs to the pads, it splits into two connectors just after the wire clamp at the caliper. Both wires run through a sheath.

The routing along the brake flex line failed. The only solution that has held up is to hang the wires freely at the front of the steering knuckle, clamped at the subframe.